Induction Based Skin Hardening Machine

Price 250000 INR/ Set

MOQ : 1 Set

Induction Based Skin Hardening Machine Specification

- Voltage

- 415 Volt (v)

- Usage

- Industrial

- Height

- 43 Centimeter (cm)

- Product Type

- Hardening Machine

- Weight

- 70 Kilograms (kg)

- Color

- White

- Oscillation Frequency

- 50-60 Kilohertz ( KHZ )

- Length

- 44 Centimeter (cm)

- Width

- 32 Centimeter (cm)

Induction Based Skin Hardening Machine Trade Information

- Minimum Order Quantity

- 1 Set

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 1 Set Per Day

- Delivery Time

- 15 Days

- Packaging Details

- Warping in bobble sheet and packing in wooden box

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Induction Based Skin Hardening Machine

Shapet Induction Hardening Machine is a type of induction furnace that produces heat on the principle of electromagnetic induction. A metal job is placed to be heated inside Induction Coil and quenched to dive, a needed transformation that makes metal hardened and brittle.We are manufacturers of Induction Hardening machines with high efficiency, durability, and reliability utilizing quality materials. We are manufacturing and supplying a broad array of Induction Hardening Machines, which are used for surface and through-hardening. Along with the offered induction hardening machine, we give solutions to auto parts, and hand tools industries also We are manufacturing customized machines according to application.

Typical applications of induction hardening include Gears, Shafts, Axles, Cam lobes, Stampings, and Spindles, mostly Symmetrical parts. Induction hardening is used to strengthen a specific area of a part. Single-piece, surface hardening of selective areas.

| Benefits |

|---|

| With induction heating technology, heat is produced instantly and directly within the part being heated. |

| Through the development of an induction coil combined with the specification of the proper power and frequency, the can isolate or pinpoint a heat-zone, small or large without affecting surrounding areas. |

| High efficiency to save energy, high efficiency, and power can be maintained. |

Efficient Surface Hardening

This innovative machine employs induction heating to deliver rapid and uniform surface hardening of metal parts. Its advanced technology ensures the treated components gain superior wear resistance and durability without compromising the core properties. With precise control via oscillation frequency, its ideal for industrial processing lines requiring consistent quality and efficiency.

Space-Saving Industrial Design

Despite its robust capabilities, the Induction Based Skin Hardening Machine comes in a compact format measuring 43 x 44 x 32 cm. Weighing 70 kg, it fits conveniently in most industrial settings where floor space can be a constraint. Its white exterior complements modern workshop environments while ensuring easy maintenance.

FAQs of Induction Based Skin Hardening Machine:

Q: How does the Induction Based Skin Hardening Machine work?

A: This machine uses high-frequency electromagnetic induction (5060 kHz) to rapidly heat the surface layer of metal components. The localized heating followed by quick cooling improves surface hardness and resistance to wear, while the core remains unaffected.Q: What types of industries typically use this machine?

A: Industries involved in automotive component manufacturing, metal tool production, machinery, and engineering sectors frequently use this machine for hardening the surfaces of critical metal parts.Q: When should I consider using an induction based skin hardening machine?

A: You should use this machine when you require improved wear-resistance, fatigue strength, and longevity in metal parts, especially when only the surface needs to be hardened while preserving internal toughness.Q: Where can I purchase or source the Induction Based Skin Hardening Machine in India?

A: This machine is available through a wide network of dealers, distributors, exporters, manufacturers, suppliers, traders, and wholesalers across India.Q: What is the process for operating this skin hardening machine?

A: The machine requires proper setup with a 415V supply. Set the oscillation frequency as per the material, then position the component in the machine. The induction coil heats the surface, followed by immediate coolingusually by water spray.Q: What are the benefits of using this machine over traditional hardening methods?

A: Induction hardening offers precise control, energy efficiency, faster processing times, and minimal material distortion. It selectively hardens the surface, resulting in a resilient component with a tough core.Q: How do I ensure consistent quality during machine usage?

A: Regular maintenance, correct parameter selection, and proper operator training are important. Also, ensure stable voltage supply and use genuine replacement parts to maintain performance and reliability.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Annealing Machine Category

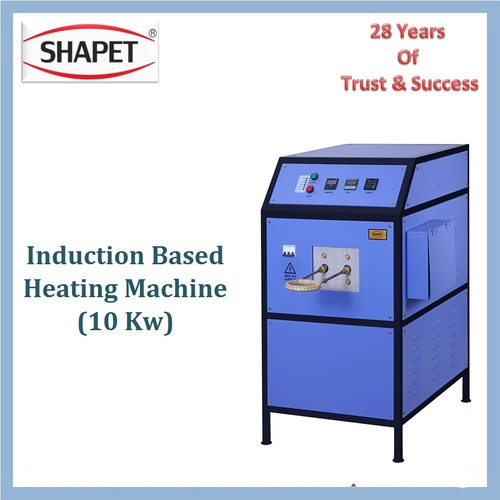

10Kw Induction Heating Machine

Price 250000 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Industrial

Product Type : Heating Machine

Weight : 180 Kilograms (kg)

Length : 56 Centimeter (cm)

Induction Based Annealing Machine

Price 265000 INR / Set

Minimum Order Quantity : 1 Set

Usage : Industrial

Product Type : Annealing Machine

Weight : 70 Kilograms (kg)

Length : 80 Centimeter (cm)

Induction Based Hardening Machine (2 In 1)

Price 300000 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Industrial

Product Type : Hardening Machine

Weight : 180 Kilograms (kg)

Length : 80 Centimeter (cm)

|

SHAPET TECHNOLOGIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry