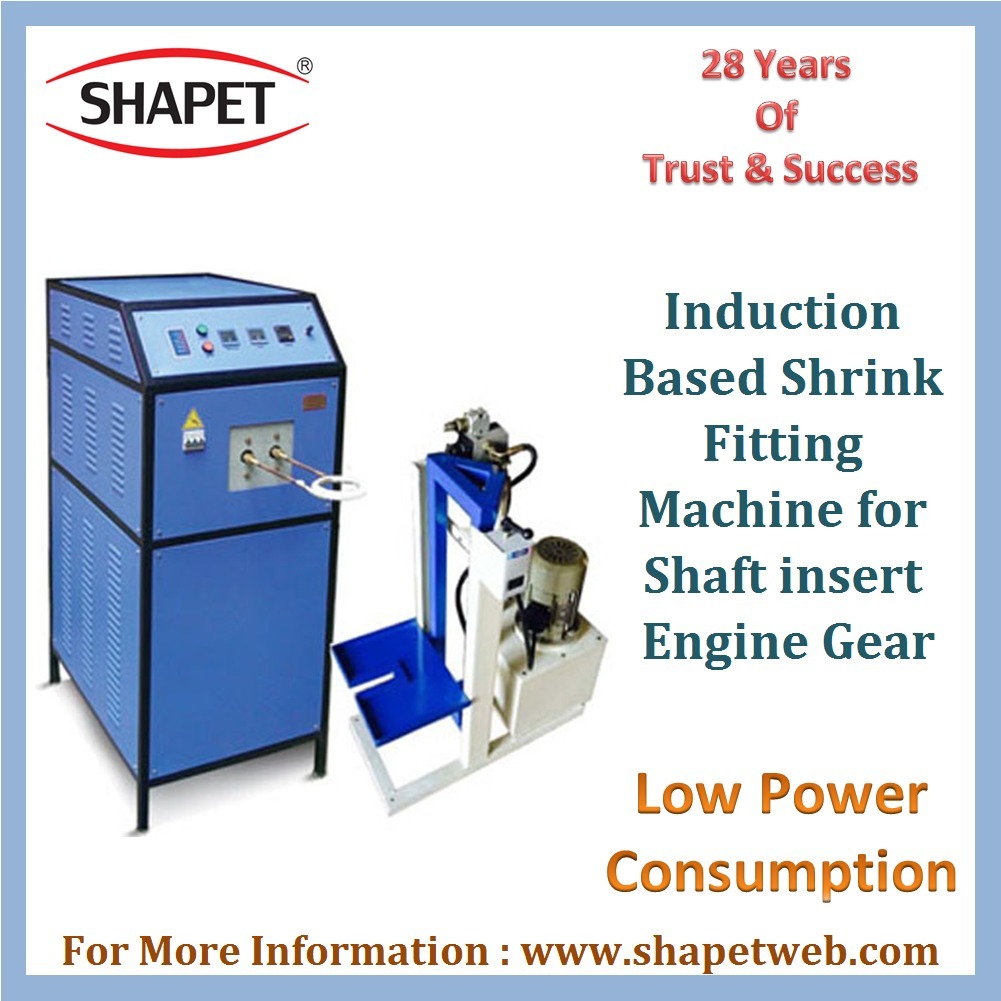

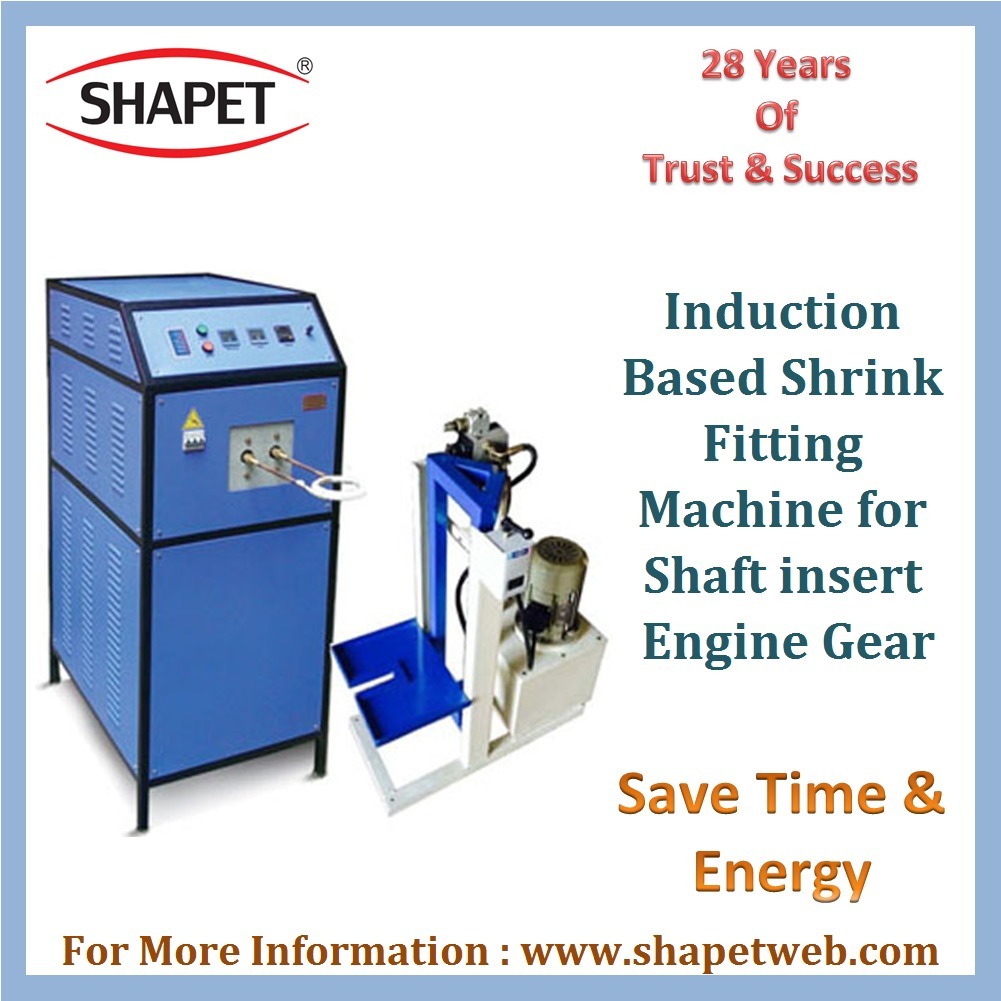

Induction Based Gear Shaft Shrink Fitting Machine

Price 340000 INR/ Set

MOQ : 1 Set

Induction Based Gear Shaft Shrink Fitting Machine Specification

- Frequency

- 50 Hertz (HZ)

- Power Source

- Electricity

- Power

- 415 Volt (v)

- Dimension (L*W*H)

- 80*60*113 Centimeter (cm)

- Weight (kg)

- 70 Kilograms (kg)

- Color

- Gray

- Warranty

- 1 Years

- Usage & Applications

- Industrial

Induction Based Gear Shaft Shrink Fitting Machine Trade Information

- Minimum Order Quantity

- 1 Set

- FOB Port

- Rajkot

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 1 Set Per Day

- Delivery Time

- 15 Days

- Packaging Details

- Warping In Bobble Sheet And Packing in wooden Box

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Induction Based Gear Shaft Shrink Fitting Machine

Engine Gear Shrink-Fitting Connections Are Simple to Join And Separate By Means of Induction Heating. Uniform Heating Expands The Outer Mating Part Without Negatively Affecting The Microstructure. This Means That A Shrink-Fitting Connection Can Be Both Produced And An Existing One Can Be Separated. Here, The Induction Coil Is Formed By Heating System Via A Special Switching Box. The Induction Heating Method Uniformly And Gently Heats The Component To Be Joined Without Producing Overheated Areas. The Generator Power For Induction Heating Is Controlled Via A Thermocouple, Which Means That The Setpoint Temperature Cannot Be Exceeded.Precision Engineering for Industrial Assembly

This shrink fitting machine is tailored to meet the demanding standards of industrial assembly lines, ensuring precise and consistent results. Its induction-based heating technology enables fast, controlled thermal expansion, making it ideal for the fitting of gear shafts and similar components without causing material stress or deformation.

User-Friendly Operation and Robust Design

Designed for easy integration into existing workflows, the machine boasts a straightforward electrical setup and controls. With its solid 70 kg build and compact dimensions, it fits efficiently into various production environments, providing durability and stability during operation for both new installations and replacement scenarios.

FAQs of Induction Based Gear Shaft Shrink Fitting Machine:

Q: How does the Induction Based Gear Shaft Shrink Fitting Machine operate?

A: The machine employs electrical induction heating to expand the gear or shaft, allowing parts to fit together tightly once cooled. Controlled heating at 50 Hertz ensures precision and uniform expansion, which prevents material damage during assembly.Q: What are the main benefits of using this shrink fitting machine?

A: Key advantages include increased assembly accuracy, reduced risk of component damage, faster processing time, and compatibility with various industrial applications. Its induction technology eliminates the need for open flames or uneven heating.Q: Where can this machine be used effectively?

A: It is suitable for factories, workshops, and manufacturing units where precise fitting of shafts and gears is required. The compact dimensions and robust structure make it adaptable to different industrial setups across India.Q: When is shrink fitting preferred over traditional assembly methods?

A: Shrink fitting is used when high-precision, stress-free joining is essential, typically in applications where gears or shafts must withstand high loads or rotational speed. It is often preferred for assemblies that require longevity and secure mechanical bonding.Q: What is involved in the shrink fitting process with this machine?

A: The process involves placing the component to be expanded on the machines heating area, applying induction heat to uniformly expand it, fitting the mating part, and allowing the assembly to cool and contract, creating a secure joint.Q: Who are the suppliers and distributors of this product in India?

A: This machine is available through authorized dealers, distributors, exporters, manufacturers, suppliers, traders, and wholesalers throughout India, each providing after-sale support and warranty service.Q: How does the one-year warranty benefit users?

A: The one-year warranty guarantees repair or replacement of defective parts due to manufacturing faults, offering buyers peace of mind and reliable after-sale support.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Shrink Fitting Machine Category

Induction Based Bearing Shrink Fitting Machine

Price 400000 INR / Set

Minimum Order Quantity : 1 Set

Warranty : 1 Years

Surface Treatment : Coated

Power Source : Electricity

Frequency : 50 Hertz (HZ)

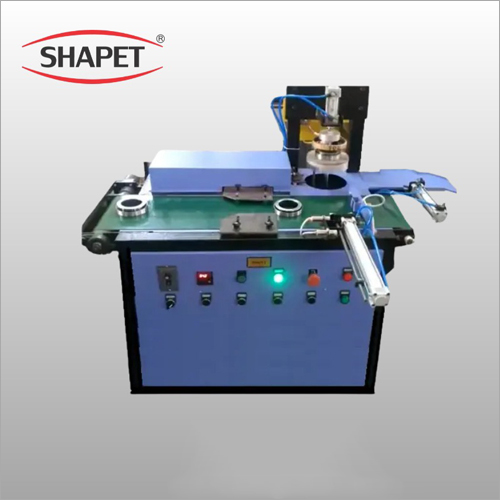

Automatic Bearing Shrink Fit Machine With Conveyar Belt

Price 230000 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : Yes

Surface Treatment : Painted

Power Source : Electricity

Frequency : 50 Hertz (HZ)

|

SHAPET TECHNOLOGIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry