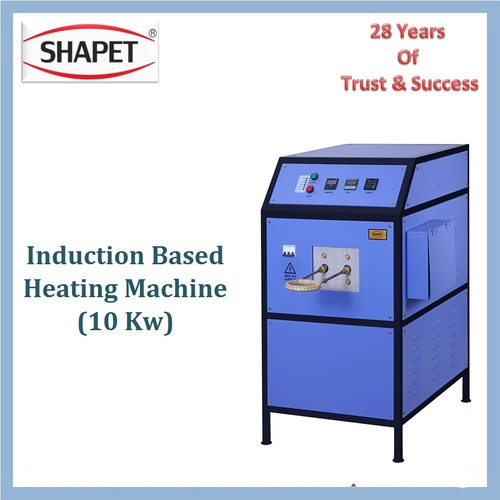

10Kw Induction Heating Machine

Price 250000 INR/ Unit

10Kw Induction Heating Machine Specification

- Voltage

- 415 Volt (v)

- Usage

- Industrial

- Height

- 113 Centimeter (cm)

- Application

- Induction Heating Machine

- Product Type

- Heating Machine

- Weight

- 180 Kilograms (kg)

- Color

- Gray

- Length

- 56 Centimeter (cm)

- Width

- 51 Centimeter (cm)

10Kw Induction Heating Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 1 Unit Per Day

- Delivery Time

- 7 Days

- Packaging Details

- Warping in bobble sheet and packing in wooden box

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About 10Kw Induction Heating Machine

Heating The Billet To Forging Temperature By Induction Heating. Any Shape & Size of Billet [Ferrous Or Non Ferrous] Can Be Heated To Required Temperature Up To The Core. Hence Forging Is Possible. Motorized or Pneumatic or Hydraulic Movement To Move Billet Inside The Coil For Heating For Continuous Production. Auto Feeder Also Available Upon Request.

Advanced Induction Heating for Jewelry Precision

Designed for the jewelry industry, our 10Kw Induction Heating Machine brings rapid, uniform heat to metals, aiding in processes such as melting, forging, and soldering. Its automatic operation streamlines workflows, ensuring increased productivity and consistent results without relying on computerized controls. Incorporating this solution into your facility means less manual intervention and fewer errors, allowing artisans and manufacturers to focus on craftsmanship.

Durable Build and Easy Integration

Constructed with industrial-grade materials and coated in a sleek gray finish, this machine balances durability with style. Compact sizing (56x51x113 cm) makes it an ideal fit for various workshop configurations, while its manageable weight (180 kg) facilitates straightforward setup and relocation. Its intuitive control panel simplifies training for operators, making it accessible even for businesses new to induction heating technologies.

FAQs of 10Kw Induction Heating Machine:

Q: How does the 10Kw Induction Heating Machine benefit the jewelry industry?

A: The machine provides rapid and uniform heating, essential for precise melting, forging, and soldering in jewelry manufacturing. This results in greater efficiency, reduced material waste, and consistently high-quality workmanship.Q: What is the process for operating this induction heating machine?

A: Operation is straightforward and automatic. Once connected to a 415-volt power supply, the operator sets the required temperature or heating time, places the metal piece in the coil, and initiates the process via the control panel.Q: Where can this induction heating machine be installed?

A: Owing to its compact size and manageable weight, the machine can be installed in small workshops, large manufacturing facilities, or dedicated jewelry production units anywhere in India with a suitable electrical setup.Q: When is this model most useful in an industrial context?

A: It is most valuable during metal heating stages that demand accuracy and speed, such as during alloy preparation, metal hardening, soldering tasks, and especially situations requiring quick turnaround and repeatable results.Q: What kind of usage is recommended for this machine?

A: As an industrial-grade tool, it is best suited for continuous, high-frequency use in environments that prioritize productivitylike jewelry fabrication plants, metal workshops, and repair centers.Q: How does automation enhance the performance of this induction heating machine?

A: The automatic feature minimizes human intervention, reduces risk of error, and boosts output consistency. Operators can rely on predefined settings to achieve desired heating outcomes with less monitoring required.Q: What are the advantages of choosing this product as a dealer, supplier, or manufacturer in India?

A: This machine offers versatility, dependability, and rapid ROI. Its robust design ensures low maintenance, while its adaptability supports varying volumes of production, making it an attractive investment for those distributing or manufacturing heating equipment nationwide.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Annealing Machine Category

Induction Based Hardening Machine (2 In 1)

Price 300000 INR / Piece

Minimum Order Quantity : 1 Piece

Weight : 180 Kilograms (kg)

Voltage : 415 Volt (v)

Height : 113 Centimeter (cm)

Color : Gray

Induction Based Annealing Machine

Price 265000 INR / Set

Minimum Order Quantity : 1 Set

Weight : 70 Kilograms (kg)

Voltage : 415 Volt (v)

Height : 113 Centimeter (cm)

Color : Gray

Induction Based Skin Hardening Machine

Price 250000 INR / Set

Minimum Order Quantity : 1 Set

Weight : 70 Kilograms (kg)

Voltage : 415 Volt (v)

Height : 43 Centimeter (cm)

Color : White

|

SHAPET TECHNOLOGIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry