Induction Based Annealing Machine

Price 265000 INR/ Set

MOQ : 1 Set

Induction Based Annealing Machine Specification

- Voltage

- 415 Volt (v)

- Usage

- Industrial

- Height

- 113 Centimeter (cm)

- Application

- Induction Annealing Machine

- Product Type

- Annealing Machine

- Max. Input Power

- 415 Volt (V)

- Weight

- 70 Kilograms (kg)

- Color

- Gray

- Width

- 60 Centimeter (cm)

- Length

- 80 Centimeter (cm)

Induction Based Annealing Machine Trade Information

- Minimum Order Quantity

- 1 Set

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 1 Set Per Day

- Delivery Time

- 15 Days

- Packaging Details

- Warping in bobble sheet and packing in wooden box

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Induction Based Annealing Machine

Induction Annealing is a heat treatment process that involves the heating of material above its recrystallization temperature. The aim is to reach and maintain a suitable temperature for enough time followed by proper cooling. It is often used in metallurgy and material science to make the treated sample more workable by reducing its hardness and increasing its ductility (ability to undergo a change of form without breaking).Induction heating provides improved control of the annealing process. Repeatable heating profiles can easily be obtained by precise regulation of the heating power. Since the workpiece is directly heated by the magnetic field, a faster response can be achieved. Moreover, the high overall efficiency of the induction heating process is crucial for such a lengthy treatment.

Reliable Induction Annealing for Industrial Needs

Our Induction Based Annealing Machine stands out with its dependable 415 Volt input, engineered to suit the rigorous demands of industrial environments. Its compact yet robust dimensions make it suitable even for workshops with space constraints while still delivering high-performance annealing results. The gray finish complements its rugged build, ensuring longevity and reduced maintenance.

Precision and Efficiency in Every Cycle

This machine uses induction heating to deliver uniform annealing, vital for achieving material softness and stress relief. The precision controls allow operators to fine-tune the process, ensuring each batch meets specific metallurgical requirements. Its efficiency not only optimizes production cycles but also provides energy savings over traditional annealing methods.

FAQs of Induction Based Annealing Machine:

Q: How does the Induction Based Annealing Machine operate?

A: This machine uses electromagnetic induction to generate heat directly within the workpiece, allowing for targeted and uniform annealing. Operators set parameters via an intuitive control panel, and the system ensures continuous and safe heating throughout the process.Q: What materials can be treated using this machine?

A: The machine is designed for a range of ferrous and non-ferrous metals, commonly used in industrial applications for stress relief, softening, or enhancing ductility in metal parts and components.Q: When is induction annealing preferred over conventional annealing methods?

A: Induction annealing is typically chosen when fast, energy-efficient, and localized heating is required. It is especially beneficial for high-volume or repetitive industrial processes due to its precise temperature control and reduced turnaround times.Q: Where can this machine be installed and used in an industrial setting?

A: The compact footprint allows installation in various facility sizes, from large production halls to smaller workshops. The machine requires a 415 Volt power connection and adequate ventilation but does not demand extensive floor space.Q: What is the typical process followed for annealing using this machine?

A: The process involves securing the workpiece near the induction coil, setting the desired parameters, and initiating the cycle. The machine heats the metal uniformly until achieving the specified temperature, after which the controlled cooling phase begins.Q: What are the primary benefits of this induction annealing machine for manufacturers and suppliers?

A: Manufacturers benefit from increased process efficiency, consistent product quality, and reduced energy usage. The precise controls minimize waste and boost productivity, enhancing overall operational output.Q: How is maintenance handled for the Induction Based Annealing Machine?

A: Routine maintenance involves regular inspections, keeping the unit clean, and checking for electrical or mechanical wear. The robust design and quality components help minimize maintenance frequency, supporting uninterrupted industrial operations.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Annealing Machine Category

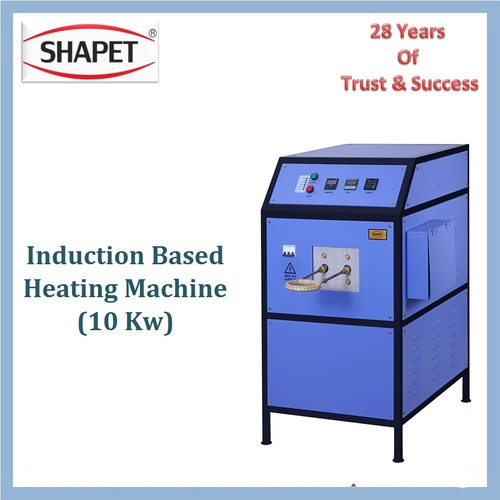

10Kw Induction Heating Machine

Price 250000 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Industrial

Weight : 180 Kilograms (kg)

Voltage : 415 Volt (v)

Width : 51 Centimeter (cm)

Induction Based Hardening Machine (2 In 1)

Price 300000 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Industrial

Weight : 180 Kilograms (kg)

Voltage : 415 Volt (v)

Width : 60 Centimeter (cm)

Induction Based Skin Hardening Machine

Price 250000 INR / Set

Minimum Order Quantity : 1 Set

Usage : Industrial

Weight : 70 Kilograms (kg)

Voltage : 415 Volt (v)

Width : 32 Centimeter (cm)

|

SHAPET TECHNOLOGIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry