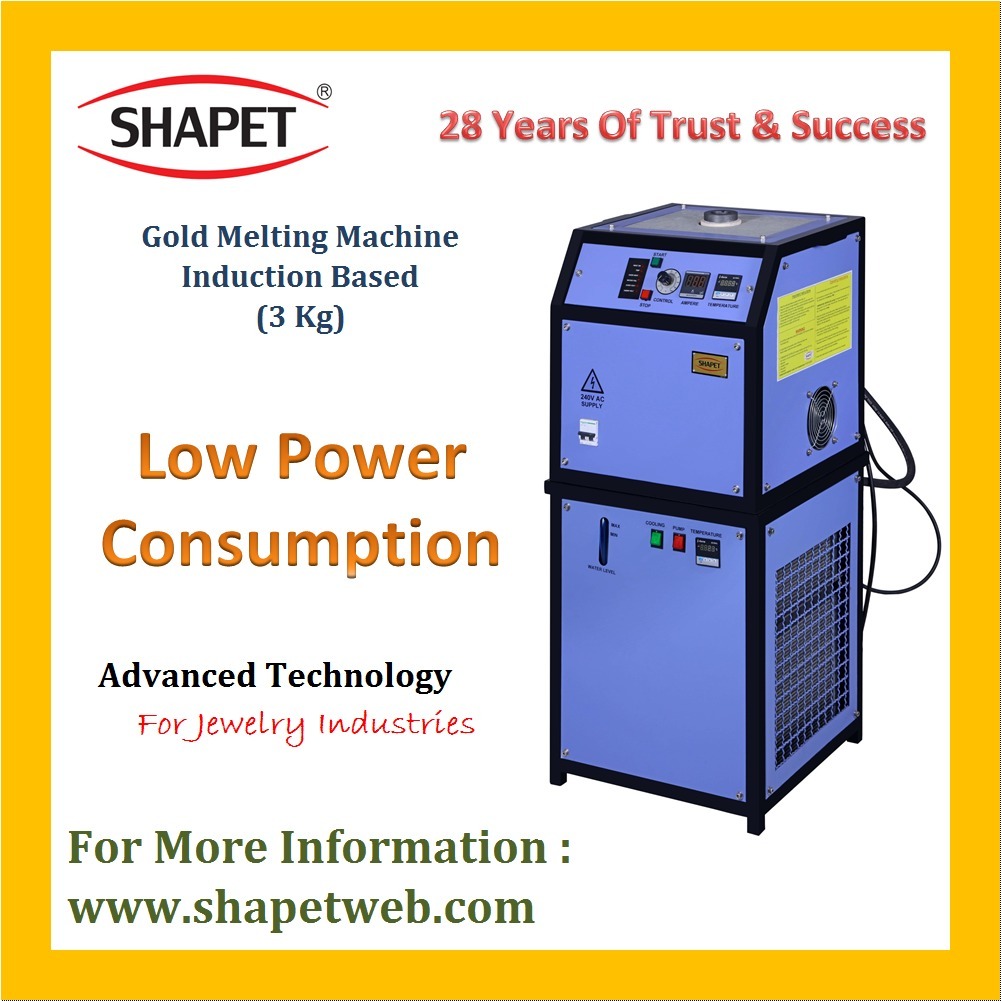

3Kg Gold Melting Machine

MOQ : 1 Set

3Kg Gold Melting Machine Specification

- Material

- Stainless Steel

- Capacity

- 3 Kg

- Computerized

- No

- Automatic

- Yes

- Control System

- PLC Control

- Cooling Mode

- Air Cooling

- Power Supply

- Electric

- Frequency (MHz)

- 50-60 Hertz (HZ)

- Voltage

- 220-240 Volt (v)

- Color

- Blue

- Warranty

- 1 Year

3Kg Gold Melting Machine Trade Information

- Minimum Order Quantity

- 1 Set

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 1 Set Per Day

- Delivery Time

- 15 Days

- Packaging Details

- Warping In Bobble Sheet and Packing In Wooden Box

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About 3Kg Gold Melting Machine

Shapet Induction Company has many years of experience with the precious metals sector and thus developed this induction system for Jewellery manufacturers and goldsmiths. It runs on the Induction principle, Absolute homogeneous alloying and uniform metal distribution with a reduction in metal losses is achieved due to uniform temperature controlling which avoids the skin effect in Shapet Induction Systems.Shape induction melting furnaces are used for a variety of special purposes, such as gold jewelry manufacturer and the manufacture of precision casts. The power output of these furnaces ranges from 3 to 5 kW, depending on the Capacity of material. For temperatures between 400 to 1150 Degree Celsius.

Shapet Induction system, the metal heats with the help of frequency and so there is no loss of heat and metal. In this method, there is auto stirring without the need of a carbon rod resulting in no loss of metal which remains pure during the entire process.

Efficient Melting for Precise Results

This gold melting machine guarantees quick and consistent gold melting utilizing advanced PLC control and automatic operation. Its high-quality stainless steel build and air cooling system ensure durability and safe handling, optimizing your precious metal workflow with minimal effort.

Compact and Powerful Design

Despite its compact dimensions of 44x44x104 cm and a weight of just 82 kg, the machine accommodates up to 3 kilograms of gold per batch. Its modern electric system (220-240V) ensures reliable performance, making it a valuable asset for professional workshops and gold processing facilities.

FAQs of 3Kg Gold Melting Machine:

Q: How does the 3Kg Gold Melting Machine operate?

A: The machine functions through a fully electric system using 220-240 volts and 50-60Hz frequency, managed by a PLC control. Operators place gold into the stainless steel chamber, select settings, and the machine automatically melts the gold efficiently with air cooling for safety.Q: What materials can be melted in this furnace?

A: Although primarily designed for gold, the sturdy stainless steel construction and advanced controls may allow melting of similar precious metals, provided their quantities and melting points are within the machines specifications.Q: When should routine maintenance be performed?

A: Regular maintenance, such as cleaning and checking the cooling system, should be performed after each batch or as recommended by the supplier. This ensures the machine continues to operate smoothly and effectively.Q: Where can this gold melting machine be installed?

A: Due to its compact size and air cooling mechanism, the machine can be installed in workshops, jewelry factories, or small industrial spaces across India, requiring only a standard electric power supply.Q: What is the process for melting gold with this machine?

A: Load the gold into the chamber, set the desired melting parameters using the PLC control, and start the automatic operation. The machine will handle the heating and melting, then cool safely via its air cooling system before allowing the gold to be retrieved.Q: How does using an electric melting furnace benefit gold dealers?

A: The electric-powered operation offers clean, efficient melting with minimal environmental impact. Dealers and manufacturers benefit from precise temperature control, faster processing, and enhanced safety during gold melting protocols.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Gold Silver Copper Induction Melting Furnace Category

250gm Silver Induction Based Melting Machine

Price 165000.0 INR / Set

Minimum Order Quantity : 1 Set

Condition : New

Automatic : Yes

Warranty : 1 Year

Usage : Melting Furnace

20Kg Gold Induction Based Melting Machine with Tilting

Price 750000 INR / Set

Minimum Order Quantity : 1 Set

Condition : New

Automatic : Yes

Warranty : 1 Year

Usage : Melting Furnace

12Kg Gold Induction Based Melting Machine With Tilting

Price 595000 INR / Set

Minimum Order Quantity : 1 Set

Condition : New

Automatic : Yes

Warranty : 1 Year

Usage : Melting Furnace

15Kg Silver Induction Based Melting Machine with Tilting

Price 6500 INR / Set

Minimum Order Quantity : 1 Set

Condition : New

Automatic : Yes

Warranty : 1 Year

Usage : Melting Furnace

|

SHAPET TECHNOLOGIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry