Burnout Furnace with Programmable Timer

Price 55000 INR/ Set

Burnout Furnace with Programmable Timer Specification

- Product Type

- Casting Plant Machinery

- General Use

- Jewelry Industries

- Computerized

- No

- Automatic

- No

- Cooling Mode

- Air Cooling

- Working Temperature

- 30 Celsius (oC)

- Accuracy

- 100 %

- Power Supply

- Single Phase

- Frequency (MHz)

- 60 Kilohertz ( KHZ )

- Voltage

- 230 Volt (v)

- Dimension (L*W*H)

- 10*10*10 Inch (in)

- Feature

- Simple Control, Polishing Tumblers, High Performance, ECO Friendly, High Efficiency, Lower Energy Consumption, Low Noise

- Color

- Gray

- Warranty

- 1 Years

Burnout Furnace with Programmable Timer Trade Information

- Minimum Order Quantity

- 1 Set

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 1 Set Per Day

- Delivery Time

- 15 Days

- Packaging Details

- Warping in bobble sheet and packing in wooden box

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Burnout Furnace with Programmable Timer

Due to our expertise, we are able to provide a high-quality Burnout Furnace that is known for high-temperature control, minimum power consumption, and durability. These furnaces are available in various specifications and Sizes and are integrated with digital controllers. We provide a surround heating coil to ensure uniform heating of all flasks.These burnout furnaces are made with superior one-piece insulation sections on all walls, instead of multiple assembled joint pieces. This ensures better heat distribution, saving of power, and long trouble-free life. It features a programable timer with a delay starting feature and is suitable also for real diamond studded wax models.

Size available in 8x8 (inch), 10x10 (inch) 12x12 (inch) 15x15 (inch) 18x18 (inch) and 22x22 (inch)

ALSO, WE MAKE BURNOUT FURNESS AS PER CUSTOMERS REQUIREMENTS.

Efficient Jewelry Processing

This Burnout Furnace is engineered to deliver high performance in jewelry manufacturing environments. Its ECO-friendly design ensures lower energy consumption, making it an ideal addition to businesses looking to enhance productivity while minimizing operational costs. The furnaces reliable accuracy supports consistent results, vital for delicate jewelry work.

Robust Build & User-Friendly Controls

Built with durability in mind, the furnace features a simple control system that eliminates complexity in daily use. Its sturdy construction supports high efficiency and minimal noise, helping maintain a comfortable workspace. The compact 10x10x10 inch size allows for flexible installation in workshops of all sizes.

FAQs of Burnout Furnace with Programmable Timer:

Q: How do you operate the Burnout Furnace with Programmable Timer?

A: To operate the furnace, simply use the straightforward control panel to set your desired timing and monitor the process. Since it is not automatic or computerized, manual adjustments are necessary for programming and monitoring during use.Q: What are the primary benefits of using this furnace in jewelry industries?

A: The main benefits include high efficiency, precise temperature accuracy, eco-friendly operation, low energy consumption, and minimal noise levels, all of which contribute to improving productivity and maintaining quality standards in jewelry manufacturing.Q: When should the furnace be used during the jewelry making process?

A: This furnace is ideally used during the burnout stage, particularly for removing wax or other residues from molds, ensuring your castings are clean and ready for the next steps in jewelry fabrication.Q: Where can this Burnout Furnace be purchased or sourced in India?

A: The furnace is widely available through dealers, distributors, exporters, manufacturers, suppliers, traders, and wholesalers across India, catering specifically to jewelry businesses.Q: What maintenance is required for optimal performance?

A: Regularly check air filters and clean the cooling vents to maintain optimal air cooling efficiency. It is also advisable to periodically inspect the control panel and ensure electrical connections are secure for reliable operation.Q: Is there a warranty provided with the furnace, and what does it cover?

A: Yes, the furnace comes with a one-year warranty, covering manufacturing defects and ensuring peace of mind for buyers in case of unlikely malfunctions.Q: What type of power supply is compatible with the furnace?

A: The furnace is designed to operate with a single-phase, 230-volt power supply, making it suitable for most jewelry workshops and standard electrical setups in India.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Jewellery Casting Machinery Set up Category

Vibrating Machine

Price 18000 INR / Piece

Minimum Order Quantity : 1 Piece

Power Supply : Single Phase

Voltage : 230 Volt (v)

General Use : Jewelry Industries

Product Type : Casting Plant Machinery

1Kg Silver Vacuum Bottom Pouring Casting Machine - Single Phase

Price 675000 INR / Set

Minimum Order Quantity : 1 Set

Power Supply : Single Phase

Voltage : 230 Volt (v)

General Use : Jewelry Industries

Product Type : Jewelry Casting Machine

Water Jet Unit

Price 75000 INR / Piece

Minimum Order Quantity : 1 Piece

Power Supply : Single Phase

Voltage : 230 Volt (v)

General Use : Jewelry Industries

Product Type : Casting Plant Machinery

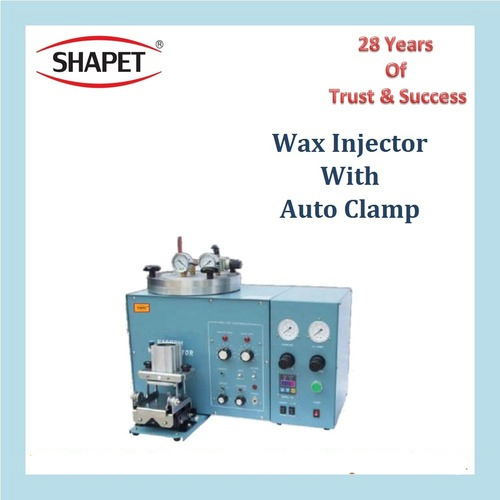

Wax Injector with Auto Clamp

Price 125000 INR / Piece

Minimum Order Quantity : 1 Piece

Power Supply : Single Phase

Voltage : 230 Volt (v)

General Use : Jewelry Industries

Product Type : Casting Plant Machinery

|

SHAPET TECHNOLOGIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry