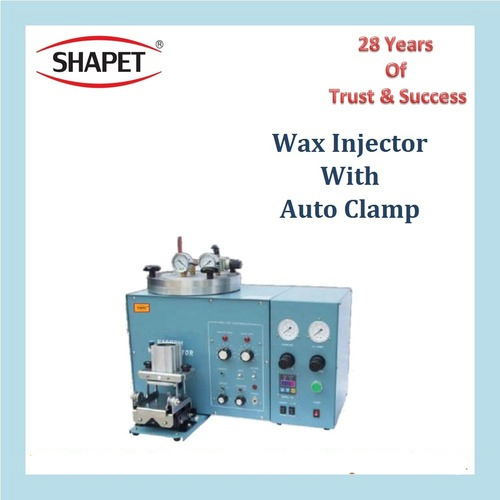

Wax Injector with Auto Clamp

Price 125000 INR/ Piece

Wax Injector with Auto Clamp Specification

- Product Type

- Casting Plant Machinery

- General Use

- Jewelry Industries

- Computerized

- No

- Automatic

- No

- Working Temperature

- 30 Celsius (oC)

- Accuracy

- 100 %

- Power Supply

- Single Phase

- Frequency (MHz)

- 60 Kilohertz ( KHZ )

- Voltage

- 230 Volt (v)

- Feature

- Simple Control, Polishing Tumblers, High Performance, ECO Friendly, High Efficiency, Lower Energy Consumption, Low Noise

- Color

- Blue

- Warranty

- 1 Years

Wax Injector with Auto Clamp Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 1 Piece Per Week

- Delivery Time

- 15 Days

- Packaging Details

- Warping in bobble sheet and packing in wooden box

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Wax Injector with Auto Clamp

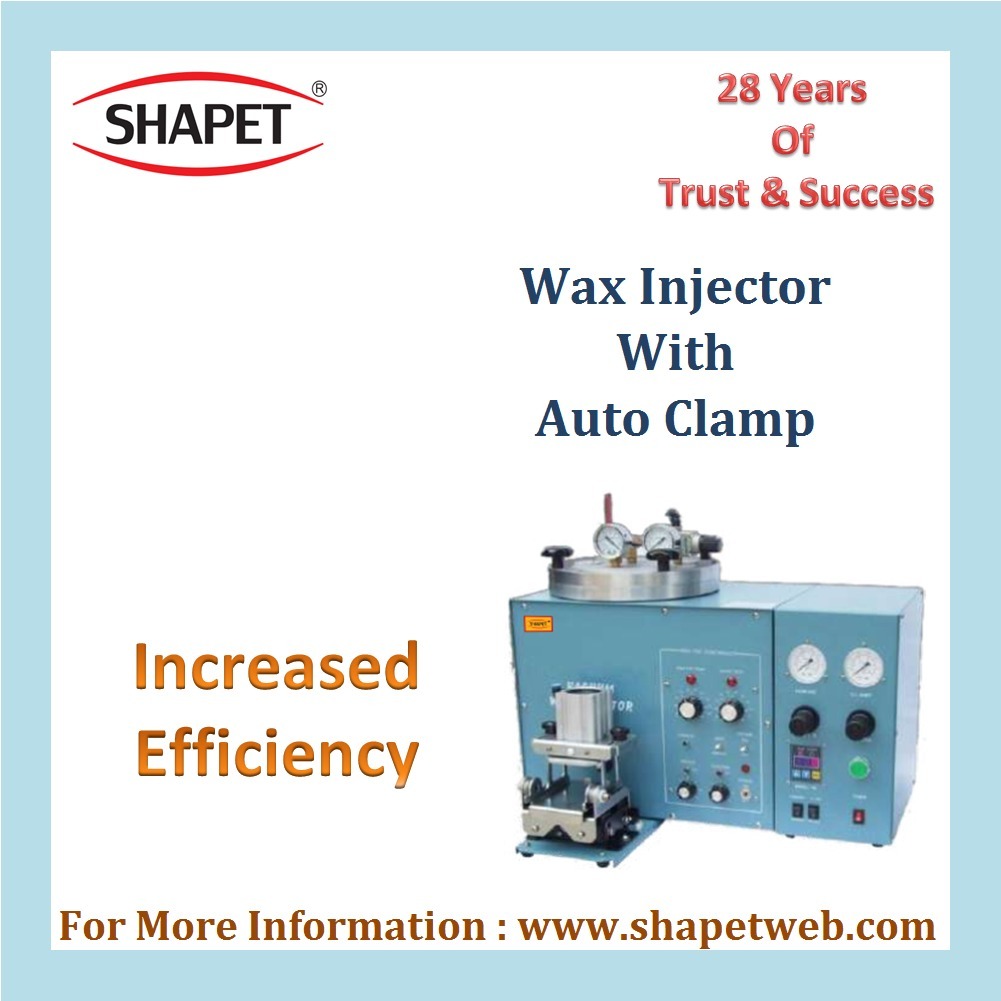

The injectors are widely used in various applications such as a digital mode for vacuum & pressure, digital temperature controller, built in tabletop body, excellent working in CAD CAM modules. These injectors are manufactured using premium quality raw material and modern technology under the supervision of experienced professionals. The quality of these injectors is tested on various parameters before delivering them to the customers.Effortless Wax Injection for Jewelry Production

Experience fast and accurate wax model creation with our Wax Injector featuring an automatic clamp. Its intuitive design enables simple operation, ideal for any jewelry industry environment. The machines high efficiency and eco-friendly technology ensure lower energy use and reduced operational noise, supporting both productivity and sustainability goals.

High Performance and Energy Efficiency

Operate with confidence using a 60 kHz frequency engine that delivers precise results every time. The combination of high efficiency and lower energy consumption keeps running costs down, while consistent performance ensures you meet demanding production schedules with ease.

FAQs of Wax Injector with Auto Clamp:

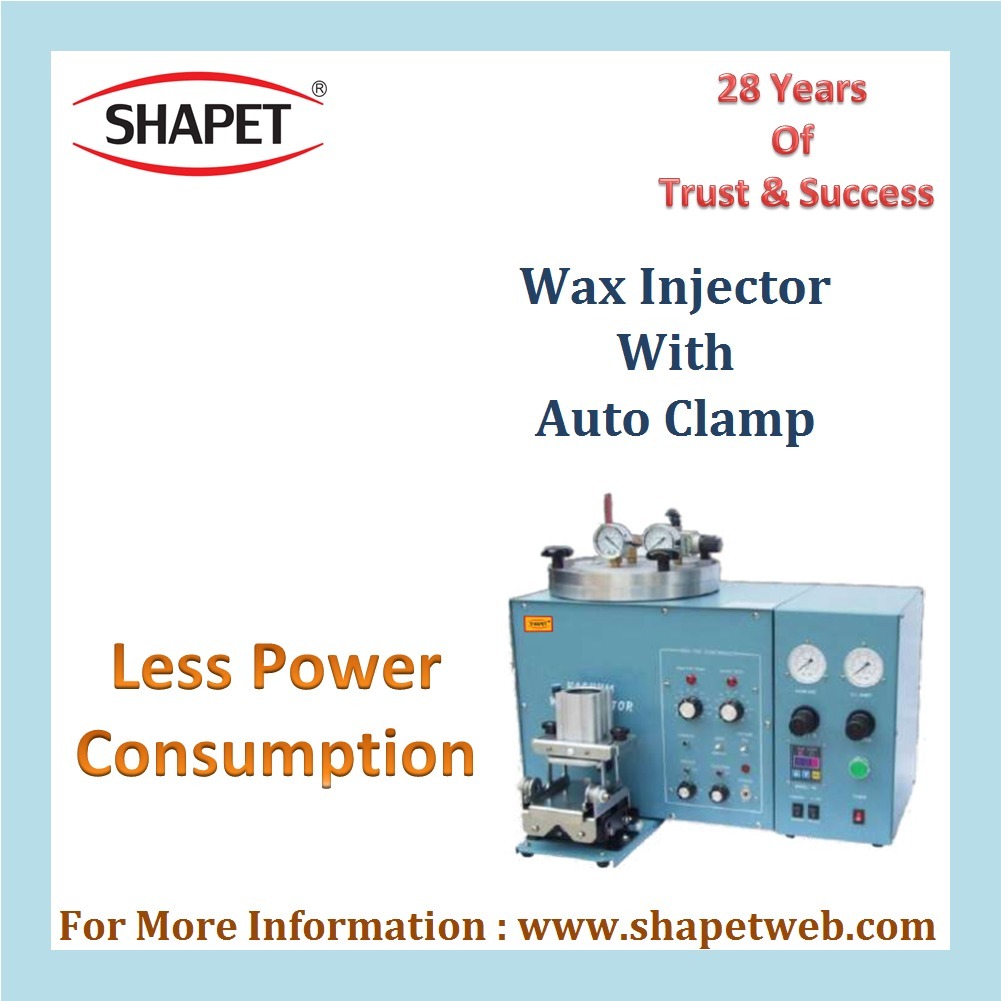

Q: How does the Auto Clamp feature improve wax injection in jewelry manufacturing?

A: The Auto Clamp securely holds molds in place during the injection process, ensuring an even distribution of wax and minimizing manual adjustments. This leads to consistently accurate wax models and enhances workplace safety and efficiency.Q: What is the recommended working temperature for the Wax Injector?

A: The ideal working temperature for this Wax Injector is 30C, which helps maintain optimal wax fluidity and prevents model defects.Q: When should I perform maintenance on the Wax Injector?

A: Regular maintenance is suggested every few weeks or after a set number of operating hours, as outlined in the product manual, to ensure optimal performance and extend the machines lifespan.Q: Where is this Wax Injector primarily used?

A: This machine is designed for use within jewelry industries, including workshops, factories, and production units, and is available to dealers, distributors, exporters, manufacturers, suppliers, traders, and wholesalers throughout India.Q: What is the process for using the Wax Injector with Auto Clamp?

A: Simply load the mold into the clamp, set the desired parameters using the simple control panel, and initiate the injection cycle. The auto clamp holds the mold securely while the device operates at 60 kHz for precise wax injection.Q: How does the machine ensure eco-friendliness and low energy consumption?

A: The Wax Injector uses advanced technology to minimize electricity usage while delivering high output. Its components are engineered for efficiency, resulting in lower energy costs and a smaller environmental footprint.Q: What benefits does this Wax Injector offer over traditional models?

A: Key benefits include precise accuracy (100%), lower operating noise, user-friendly controls, and enhanced energy efficiency. These features contribute to higher productivity and reduced operational expenses in jewelry manufacturing.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Jewellery Casting Machinery Set up Category

Vibrating Machine

Price 18000 INR / Piece

Minimum Order Quantity : 1 Piece

Power Supply : Single Phase

Voltage : 230 Volt (v)

General Use : Jewelry Industries

Product Type : Casting Plant Machinery

Water Jet Unit

Price 75000 INR / Piece

Minimum Order Quantity : 1 Piece

Power Supply : Single Phase

Voltage : 230 Volt (v)

General Use : Jewelry Industries

Product Type : Casting Plant Machinery

Burnout Furnace with Programmable Timer

Price 55000 INR / Set

Minimum Order Quantity : 1 Set

Power Supply : Single Phase

Voltage : 230 Volt (v)

General Use : Jewelry Industries

Product Type : Casting Plant Machinery

Die Press Machine

Price 26000 INR / Piece

Minimum Order Quantity : 1 Piece

Power Supply : Single Phase

Voltage : 230 Volt (v)

General Use : Jewelry Industries

Product Type : Casting Plant Machinery

|

SHAPET TECHNOLOGIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry