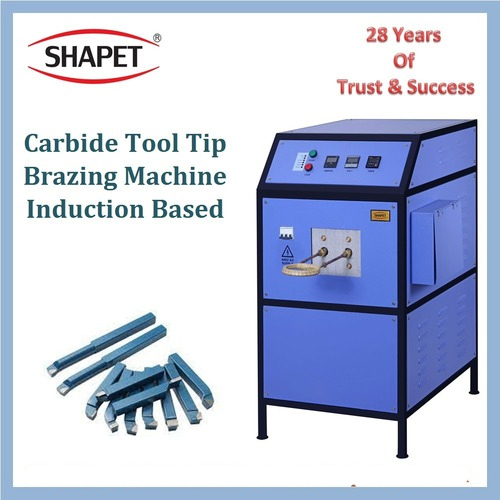

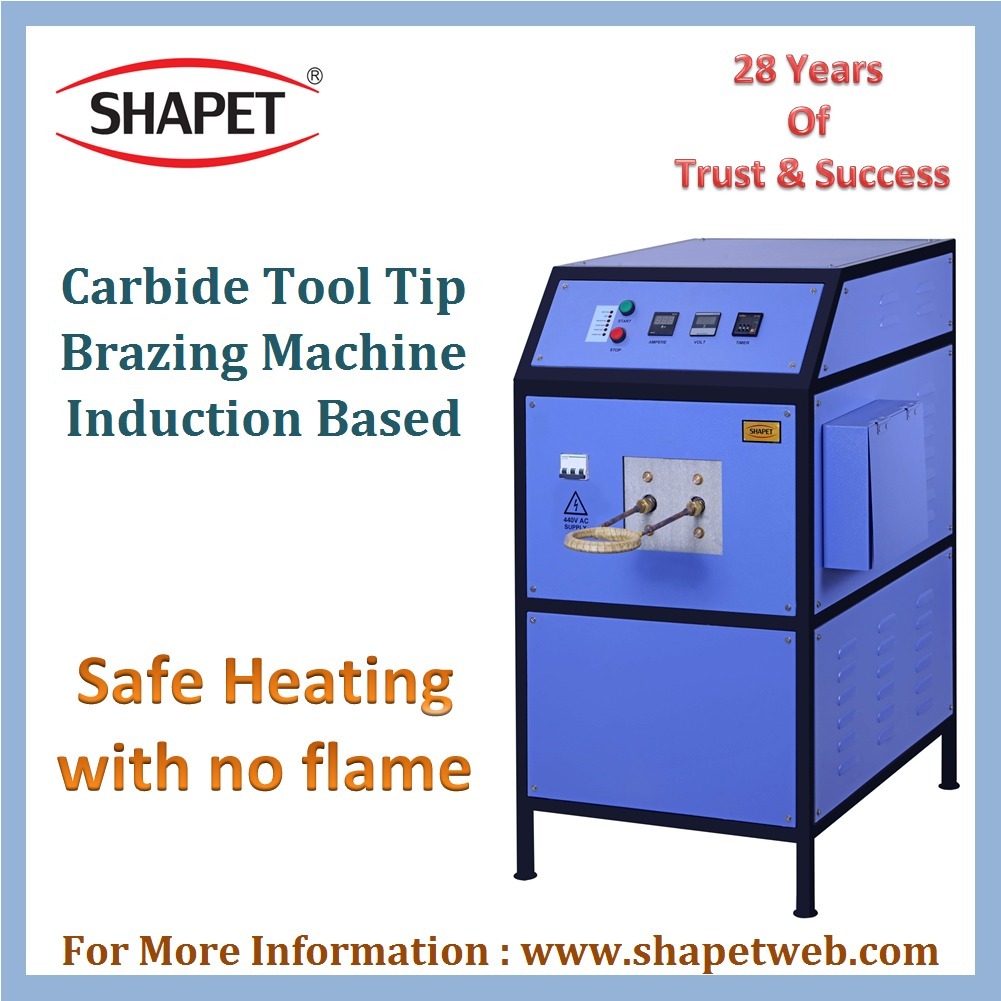

Carbide Tool Tip Brazing Machine

Price 265000 INR/ Set

MOQ : 1 Set

Carbide Tool Tip Brazing Machine Specification

- Voltage

- 415 Volt (v)

- Usage

- Industrial

- Height

- 113 Centimeter (cm)

- Product Type

- Brazing Machine

- Max. Input Power

- 415 Volt (V)

- Weight

- 70 Kilograms (kg)

- Color

- Gray

- Oscillation Frequency

- 50-60 Hertz (HZ)

- Width

- 60 Centimeter (cm)

- Length

- 80 Centimeter (cm)

Carbide Tool Tip Brazing Machine Trade Information

- Minimum Order Quantity

- 1 Set

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 1 Set Per Day

- Delivery Time

- 15 Days

- Packaging Details

- Warping in bobble sheet and Packing in wooden Box

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Carbide Tool Tip Brazing Machine

Carbide Tipping is specific brazing process by which a hardened tip material is applied to a base material to produce an extremely hard cutting edge. When using induction heating, the tipping material is brazed to the base material with temperatures up to 1000 to 1100 DegreeCelsiusTipped with carbide segments, the brazed tools provide a cutting surface with the combined characteristics of compressive strength, extreme hot hardness at high temperatures, and resistance to abrasion, corrosion and thermal shock.

Precision and Durability

Our Carbide Tool Tip Brazing Machine is acclaimed for its precision and long-lasting performance in industrial environments. Crafted to handle intense operating conditions, it maintains consistent results, ensuring your carbide tools are securely brazed for optimal use.

User-Friendly Industrial Design

With compact dimensions and a manageable weight of 70 kg, this machine fits seamlessly into production lines. The straightforward operation and easily accessible controls make it suitable for both experienced technicians and new operators.

Reliable Power and Flexibility

Operating on 415 Volt input and adaptable to 50-60 Hertz frequency, the machine is compatible with diverse industrial power settings. Its stable electrical configuration supports efficient and reliable operation, enhancing productivity and reducing downtime.

FAQs of Carbide Tool Tip Brazing Machine:

Q: How does the Carbide Tool Tip Brazing Machine benefit industrial operations?

A: The machine provides reliable and precise carbide tip brazing, improving tooling durability and reducing maintenance frequency, which enhances overall production efficiency for industrial users.Q: What is the process for operating the Carbide Tool Tip Brazing Machine?

A: First, set up the machine on a stable surface and connect it to a 415 Volt power source. Secure the tool and carbide tip, adjust necessary settings, and initiate the brazing cycle through the machines control panel following safety protocols.Q: When is it recommended to use this machine?

A: This machine is best used during any carbiding or tip-brazing stage in the production or repair of cutting tools. It is ideal whenever consistent and strong joints are required between carbide tips and tool bodies.Q: Where can I purchase or source this machine in India?

A: You can find the Carbide Tool Tip Brazing Machine through authorized dealers, distributors, exporters, manufacturers, suppliers, traders, and wholesalers across India.Q: What safety precautions should be followed during usage?

A: Operators should wear protective gear, ensure the workspace is well-ventilated, and follow all operating guidelines provided in the manual to prevent accidents or equipment damage.Q: How is the machine maintained for optimum performance?

A: Routine maintenance involves regular cleaning, inspecting electrical connections, checking for wear on moving parts, and ensuring that all safety mechanisms are functioning as intended.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Induction Brazing Machine Category

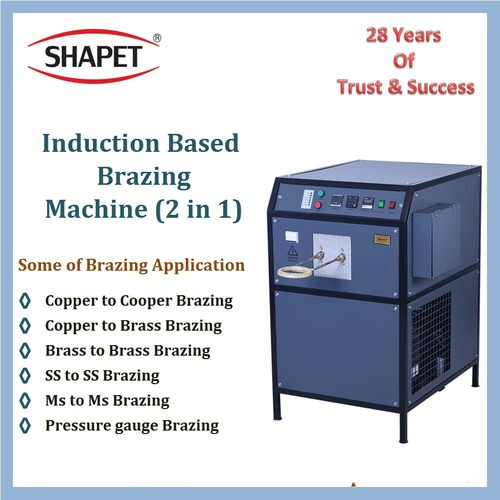

Induction Brazing Machine (2 in 1)

Price 265000 INR / Set

Minimum Order Quantity : 1 Set

Application : Induction Brazing Machine

Voltage : 415 Volt (v)

Oscillation Frequency : 5060 Hertz (HZ)

Color : Gray

Submersible Rotor Induction Brazing Machine

Price 230000 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Industrial

Voltage : 220 Volt (v)

Oscillation Frequency : 50 Hertz (HZ)

Color : Black, Silver, Blue

|

SHAPET TECHNOLOGIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry