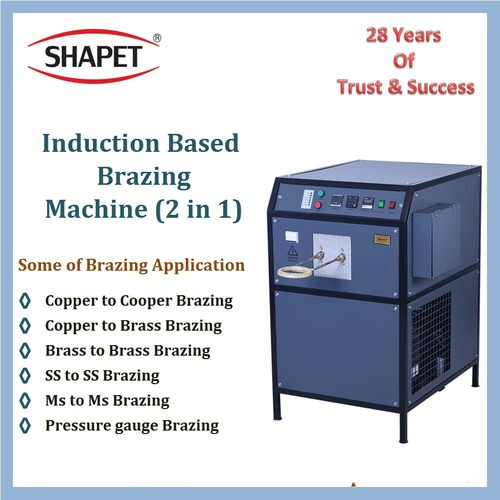

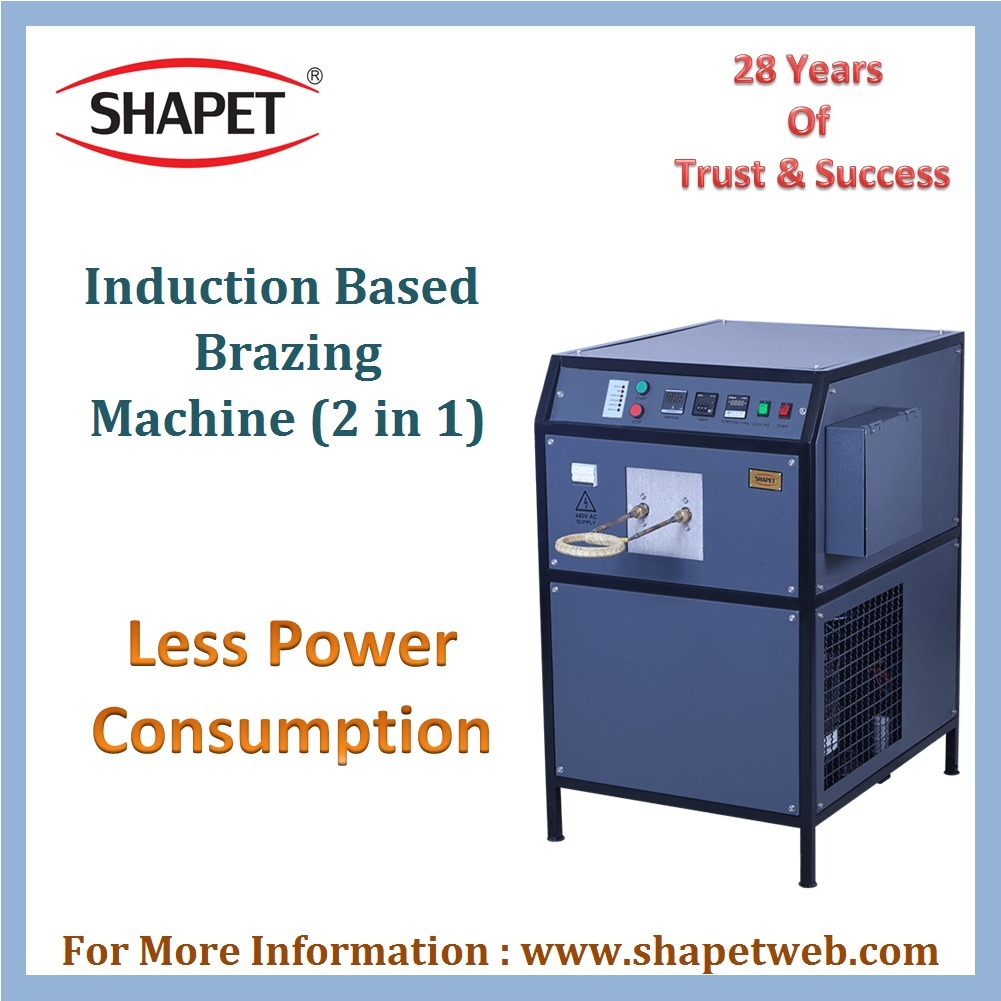

Induction Brazing Machine (2 in 1)

Price 265000 INR/ Set

MOQ : 1 Set

Induction Brazing Machine (2 in 1) Specification

- Voltage

- 415 Volt (v)

- Usage

- Industrial

- Height

- 113 Centimeter (cm)

- Application

- Induction Brazing Machine

- Product Type

- Brazing Machine

- Max. Input Power

- 415 Volt (V)

- Weight

- 70 Kilograms (kg)

- Oscillation Frequency

- 50-60 Hertz (HZ)

- Color

- Gray

- Width

- 60 Centimeter (cm)

- Length

- 80 Centimeter (cm)

Induction Brazing Machine (2 in 1) Trade Information

- Minimum Order Quantity

- 1 Set

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 1 Set Per Day

- Delivery Time

- 15 Days

- Packaging Details

- Warping in bobble sheet and packing in wooden box

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Induction Brazing Machine (2 in 1)

Induction brazing is the process of joining two or more metals using induction heating. Induction heating utilizes the electromagnetic field to provide heat without contact or flame. Induction brazing is more localized, repeatable, and easier to automate compared to traditional torch brazing. Induction brazing has been around for a long time but is only now coming into wider use due to advancements in induction heating power supplies.Induction brazing can be used to join a wide variety of metals, including nickel, copper, cobalt, titanium, and steel. Some non-metals, such as ceramics, graphite, and glass can also be brazed using induction. It is a great way to join dissimilar metals and alloys, thanks to its localized heat and ability to join metals without melting them. Because induction brazing uses an electromagnetic field rather than flame, it can be used in many places where flame brazing is not possible or not safe.

Effortlessly Streamlined Brazing

The 2 in 1 Induction Brazing Machine is designed for seamless industrial use, providing a combination of innovative features in one robust unit. Its high-frequency operation creates uniform heat distribution for precise brazing, reducing the risk of defects in finished products. The intuitive controls and sturdy construction ensure long-term performance, catering to diverse industrial needs.

Tailored for Industrial Environments

With precise dimensions (60 cm x 80 cm x 113 cm) and a manageable weight of 70 kg, this brazing machine integrates easily into existing production lines. Its gray finish offers a modern touch, while the volt capacity and frequency align with standard industrial power supplies. This blend of design and function guarantees adaptability and efficiency for Indian manufacturers and suppliers.

FAQs of Induction Brazing Machine (2 in 1):

Q: How does the Induction Brazing Machine (2 in 1) work in an industrial setting?

A: This machine uses electromagnetic induction to rapidly heat metal parts for brazing, allowing efficient and consistent joining of materials without direct flame contact. Its 2 in 1 capability supports multiple brazing operations within the same system, increasing productivity in industrial environments.Q: What are the primary benefits of using this induction brazing machine?

A: Key benefits include fast and uniform heating, reduced energy consumption, high efficiency, and enhanced safety. The precise control of heat minimizes the risk of material distortion, enabling superior joint strength and improved product quality.Q: When is the ideal scenario to use an induction brazing machine?

A: Induction brazing machines are best utilized when precise, repeatable heating is requiredtypically in the production of automotive, electronics, or HVAC components where consistent, high-quality metal joints are essential.Q: Where can this machine be deployed within an industrial facility?

A: Due to its streamlined dimensions (60 cm width, 80 cm length, 113 cm height), this machine can be integrated into various sections of an industrial floor such as assembly lines, fabrication zones, or dedicated brazing areas.Q: What is the process involved in using this induction brazing machine?

A: The brazing process involves positioning the workpieces, applying brazing filler, and activating the induction machine. Electromagnetic fields generate heat in the joint area, melting the filler to create a strong, clean bond without the need for direct flame.Q: How is the machine powered and what are the installation requirements?

A: The machine operates on a 415-volt supply at 50-60 Hz, which is standard in many industrial facilities. It should be installed on a stable surface, and proper electrical safety protocols must be followed during setup and operation to ensure safe use.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Induction Brazing Machine Category

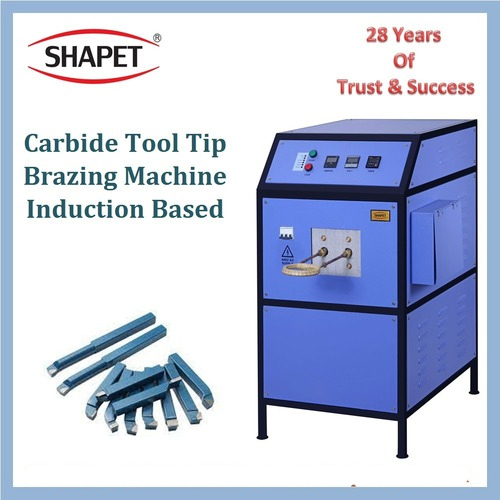

Carbide Tool Tip Brazing Machine

Price 265000 INR / Set

Minimum Order Quantity : 1 Set

Voltage : 415 Volt (v)

Color : Gray

Oscillation Frequency : 5060 Hertz (HZ)

Usage : Industrial

Submersible Rotor Induction Brazing Machine

Price 230000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 220 Volt (v)

Color : Black, Silver, Blue

Oscillation Frequency : 50 Hertz (HZ)

Usage : Industrial

|

SHAPET TECHNOLOGIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry